Reasons for issues in the radiator of a mining dumper leading to overheating, coolant leaks, or inefficient heat dissipation

Radiator problems in mining dumpers can significantly impact equipment performance and productivity. Common issues include coolant leaks, clogging, or overheating, which can result from a variety of factors such as wear and tear, improper maintenance, or environmental conditions. Coolant leaks may occur due to corrosion, damaged hoses, or loose fittings, leading to coolant loss and engine overheating. Clogging of the radiator fins with dust, debris, or mineral deposits can restrict airflow, reducing cooling efficiency and causing engine overheating. Moreover, operating in harsh mining environments with high temperatures, dust, and debris can accelerate radiator deterioration and exacerbate cooling problems. Addressing radiator problems requires regular inspection, proactive maintenance, and prompt repairs to ensure proper cooling system function, prevent equipment downtime, and maintain optimal performance of mining dumpers in demanding operating conditions.

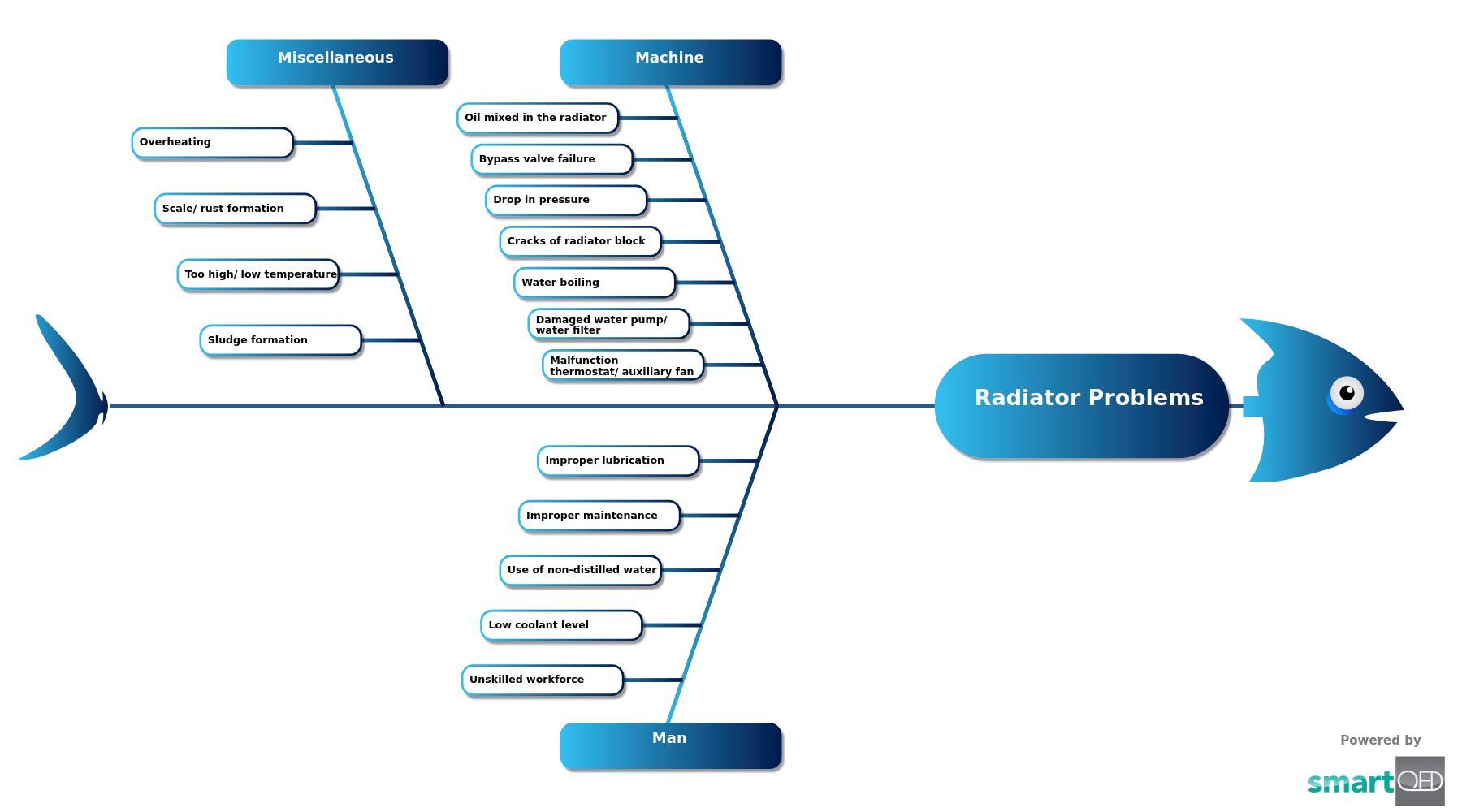

Radiator Problem

Machine

Man

Miscellaneous

The Root Cause Analysis for radiator problems in mining dumpers identifies and addresses the underlying factors causing radiator issues. The process involves gathering information meticulously and constructing a comprehensive fishbone diagram. Investigators systematically examine potential causes and implement necessary corrective actions.

Curated from community experience and public sources: