Reasons for downtime in manufacturing

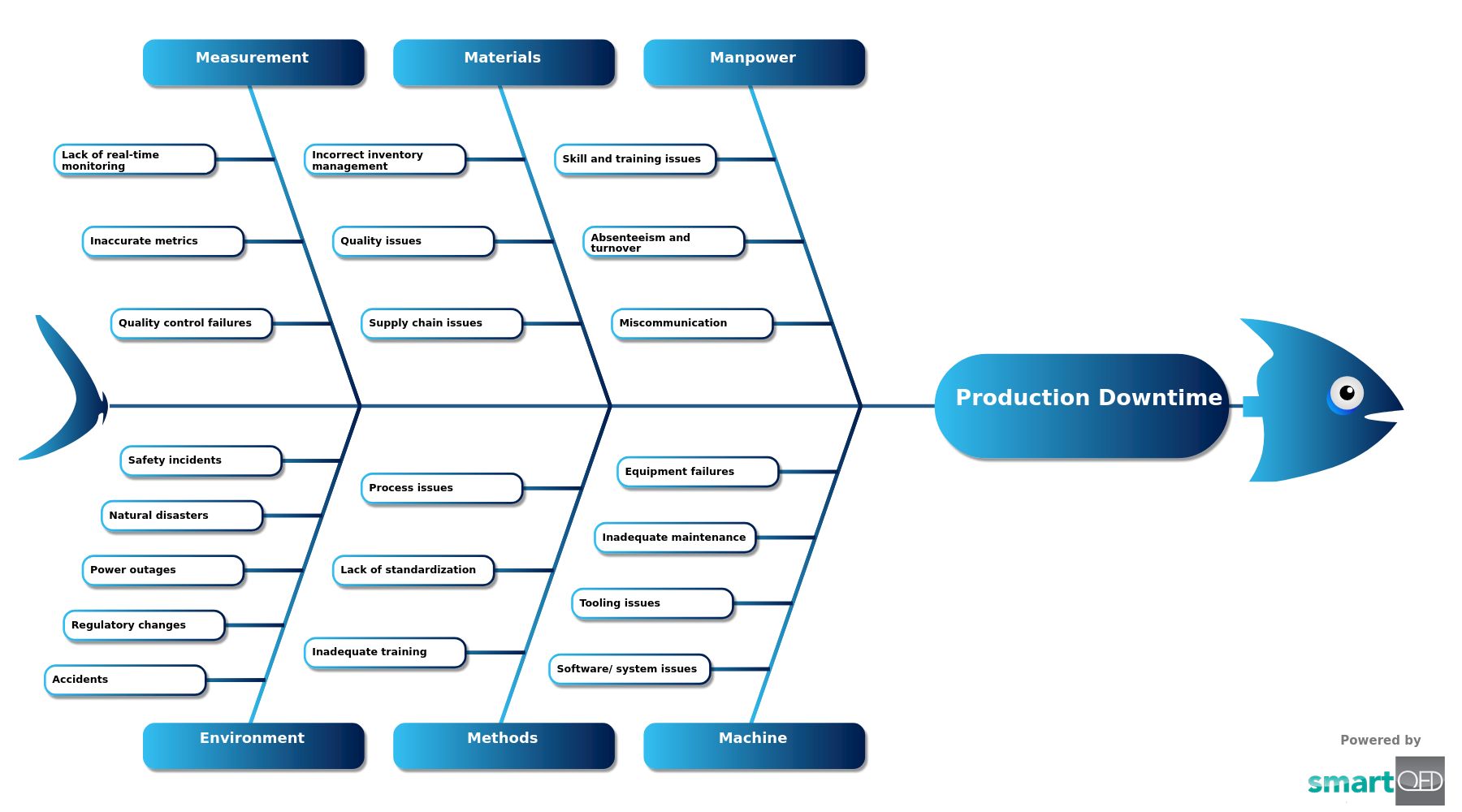

Manufacturers aim to reduce production downtime actively to improve efficiency, meet production targets, and enhance overall competitiveness in the market. Achieving this goal requires enforcing efficient scheduling, proactive and predictive maintenance, and utilizing advanced technologies for monitoring. Various factors in manufacturing settings can contribute to production downtime, often categorized using the 5M 1E framework. This framework breaks down potential causes into five elements – Manpower, Machines, Materials, Methods, and Measurement and Environment. Each of these elements can contribute to production downtime in distinct ways.

Production Downtime

Manpower

Machine

Materials

Methods

Measurement

Environment

This fishbone is a fine example of a root cause analysis done on Production Downtime. The Ishikawa diagram contains the main reasons for the failure of an ongoing manufacturing process.

Curated from community experience and public sources: