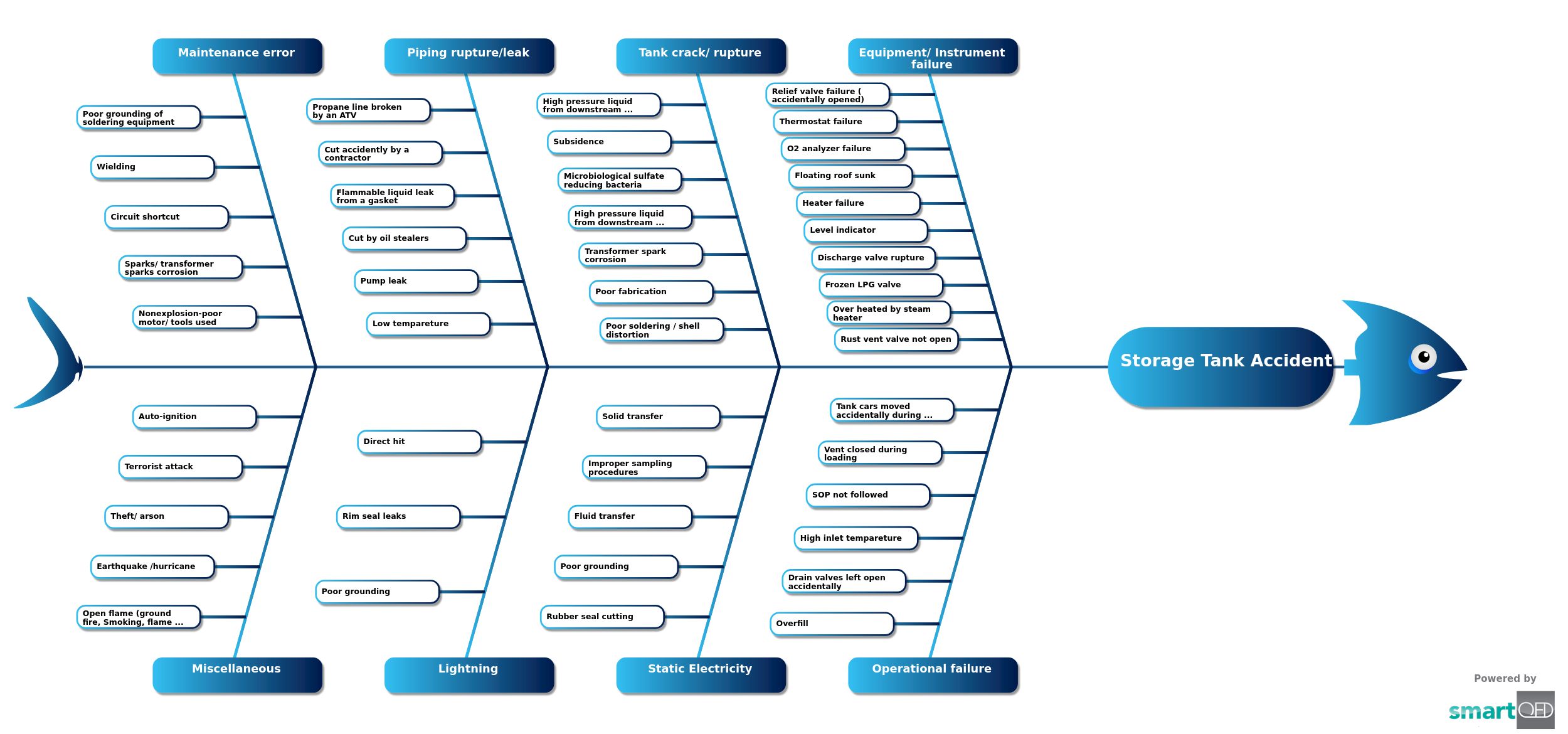

Oil tanks and chemical storage tanks have been the cause of many devastating accidents. A thorough analysis is necessary to ensure proper safety guidelines and accident-prevention measures.

Studies have shown that 74% of accidents occurring in storage tanks happen in petroleum refineries, oil terminals, or storage facilities. Fire and explosion account for 85% of these accidents. Lightning strikes are a significant cause of accidents. The role of human errors, including poor operations and maintenance, cannot be ignored. In recent years, we have witnessed several tank accidents across China, such as the tank explosion at CNPC Lanzhou Petrochemical Company, the flash explosion at CNPC Dalian Petrochemical Company, and the fire and explosion in Rizhao.

Equipment/ instrument failure

- Relief valve failure ( accidentally opened)

- Thermostat failure

- O2 analyzer failure

- Floating roof sunk

- Heater failure

- Level indicator

- Discharge valve rupture

- Frozen LPG valve

- Over heated by steam heater

- Rust vent valve not open

Operational failure

- Overfill

- Drain valves left open accidentally

- High inlet temperature

- SOP not followed

- Vent closed during loading

- Tank cars moved accidentally during loading

Rupture/leak

- Propane line broken by an ATV

- Cut accidently by a contractor

- Flammable liquid leak from a gasket

- Cut by oil stealers

- Pump leak

- Low temperature

Static electricity

- Rubber seal cutting

- Poor grounding

- Fluid transfer

- Improper sampling procedures

- Solid Transfer

Tank crack/ rupture

- High pressure liquid from downstream vessels back up

- Subsidence

- Microbiological sulfate reducing bacteria

- High pressure liquid from downstream vessels back up

- Transformer spark corrosion

- Poor fabrication

- Poor soldering / shell distortion

Lightning

- Poor grounding

- Rim seal leaks

- Direct hit

Maintenance error

- Poor grounding of soldering equipment

- Wielding

- Circuit shortcut

- Sparks/ transformer sparks corrosion

- Nonexplosion-poor motor/ tools used

Miscellaneous

- Open flame (ground fire, smoking, flame, etc.)

- Earthquake /hurricane

- Theft/ arson

- Terrorist attack

- Auto-ignition

The cause analysis facilitates easy identification of the vital causes of mishaps in chemical and oil industries.

Who should use the Storage Tank Accident template?

- If anyone is interested in knowing the causes that initiate storage tanks accidents in refineries and chemical plants.

Why use this template?

- This fishbone diagram helps perform root cause analysis of accidents in storage or reservoirs holding inflammable things.

- Anyone can change or redesign the template in the smartQED environment while troubleshooting the problem.

- Create or customize your templates for problem and incident analysis in smartQED.

Curated from community experience public sources: