Welding defects can compromise the integrity and quality of welded joints, leading to potential structural failures or performance issues. Defects such as porosity, lack of fusion, cracks, and undercutting can occur due to incorrect welding parameters, inadequate shielding gas, or poor material preparation. Detecting and addressing these glitches is essential to ensure the strength and durability of welded structures. Quality control measures, such as visual inspections, non-destructive testing, and adherence to welding procedures, are critical in minimizing these faults and maintaining the reliability of welded components across various industries, including construction, manufacturing, and infrastructure development.

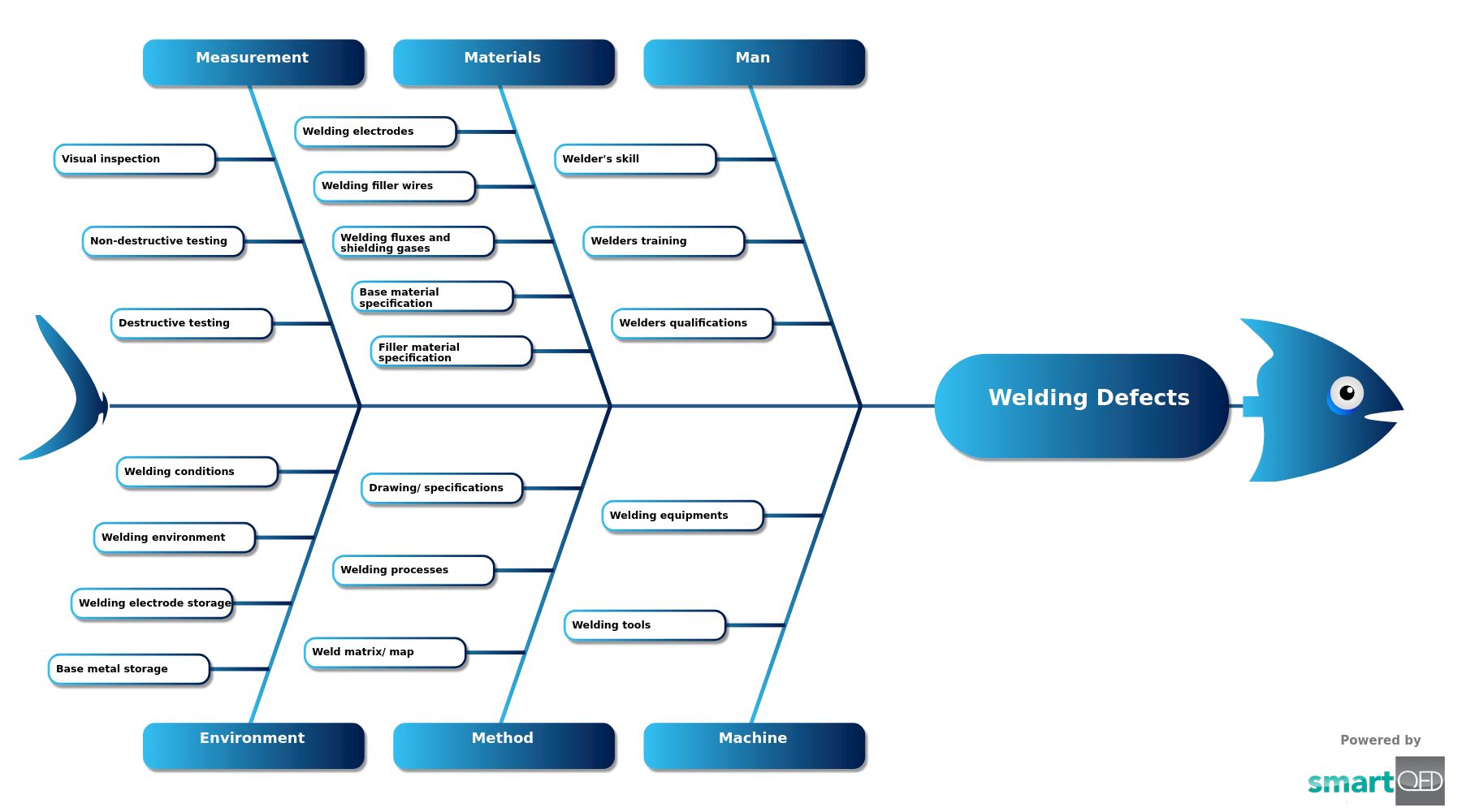

Welding Defects

Man

- Welders’ skill

- Welders’ training

- Welders’ qualifications

Machine

- Welding tools

- Welding equipment

Materials

- Welding electrodes

- Welding filler wires

- Welding fluxes and shielding gases

- Base material specification

- Filler material specification

Method

- Weld matrix / map

- Welding processes

- Drawing/ specifications

Measurement

- Visual inspection

- Non-destructive testing

- Destructive testing

Environment

- Base metal storage

- Welding electrode storage

- Welding environment

- Welding conditions

Who should use the Welding Defects template?

- Various stakeholders involved in the welding process, including welders, welding engineers, quality control personnel, supervisors, and management, will find this template helpful.

- Each stakeholder plays a crucial role in identifying, analyzing, and addressing weld defects to ensure the quality and integrity of welded products.

Why use this template?

- The RCA Fishbone analysis can effectively uncover root causes such as welding parameter deviations, material issues, equipment malfunctions, or procedural errors.

- Collaborative efforts among team members facilitate the implementation of corrective actions and preventive measures to mitigate these flaws, improve welding processes, and enhance overall product quality and safety.

Curated from community experience and public sources: