Reasons for mechanical failure of transformer windings

Transformer failure often occurs due to mechanical issues with its windings. Windings, arranged as cylindrical shells around the core limb, must endure dielectric stress, thermal demands, and mechanical forces, potentially leading to displacement. These forces, such as those from short circuits or lightning strikes, play a significant role. Understanding axial and radial forces is essential for analyzing the mechanical failure of transformer windings. These forces cause the windings to deform mechanically. Short circuits in windings can stem from various sources: mechanical faults during construction, insulation flaws, hot spot formation, copper sludge buildup, or low oil levels. Transient overvoltage may arise from lightning strikes, incorrect transformer connections, or short circuits in the low-tension system.

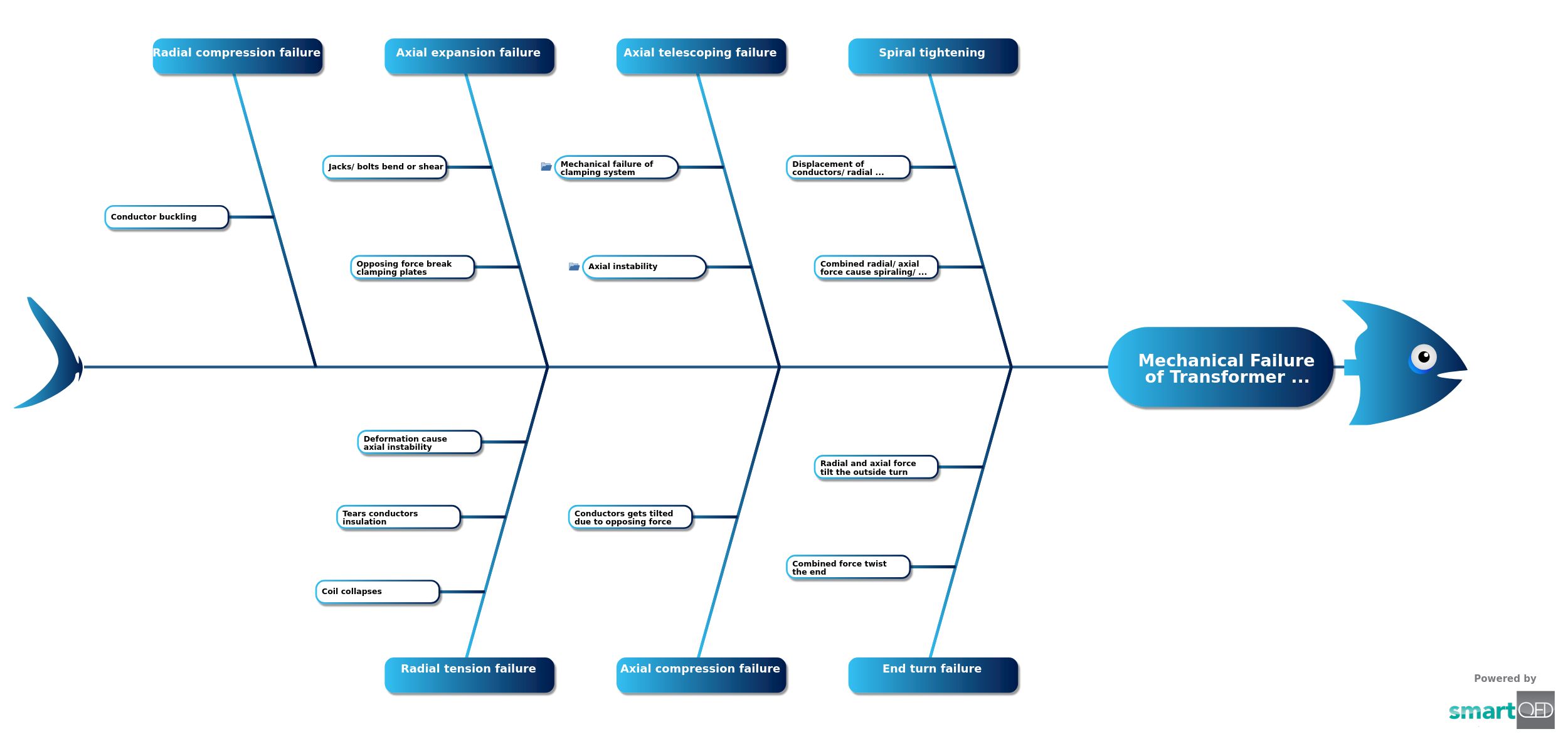

Mechanical Failure of Transformer Windings

Spiral tightening

End turn failure

Axial telescoping failure

Axial compression failure

Axial expansion failure

Radial tension failure

Radial compression failure

In summary, RCA is instrumental in understanding the mechanical failure of transformer windings, enabling organizations to address root causes, enhance maintenance practices, improve design and engineering, enhance safety and reliability, reduce costs, and foster continuous improvement in transformer operations.

Curated from community experience and public sources: