Helps identify and address problems in areas such as manpower, methods, machines, materials, measurements, environment, management, and maintenance.

In manufacturing, the 8M framework helps us understand and manage factors that affect the production process. These eight elements can help us improve our manufacturing operations and make better-quality products. The 8M’s cover everything we need to succeed in manufacturing.

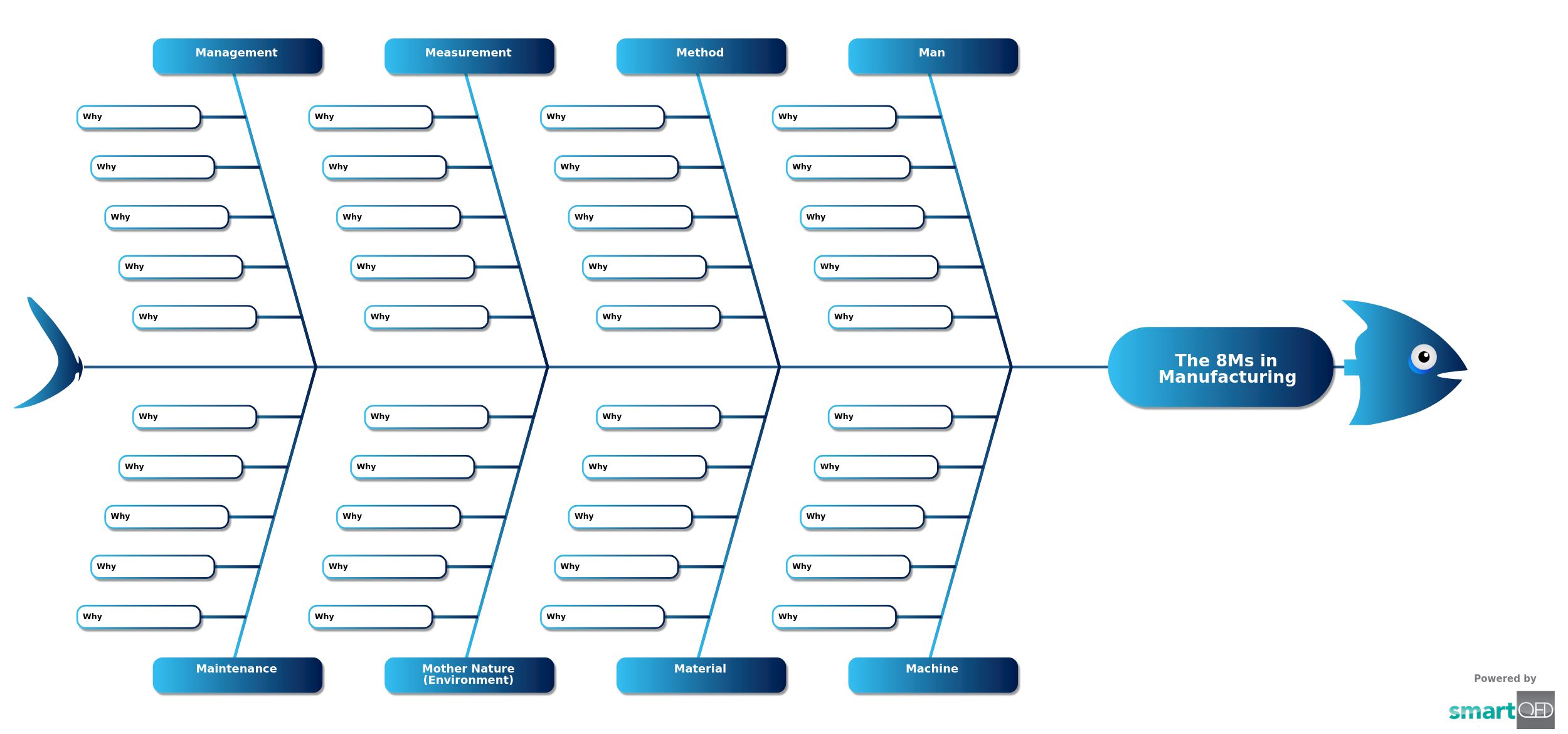

The 8Ms in Manufacturing

Man

- Here “Man” means the people who work in manufacturing. These include workers, technicians, engineers, and others. Well-trained and motivated employees are crucial for productivity, quality, and safety.

Machine

- Machinery means the equipment we use in manufacturing, like machines, tools, and vehicles. It is necessary to have reliable machinery that is well-maintained to keep production running smoothly and make more products.

Method

- Methods are the processes and techniques we use in manufacturing. These include procedures, work instructions, and quality control. We can reduce waste and improve productivity and quality by using these methods.

Material

- Materials indicate the items we use to make our products like raw materials. Good-quality materials that are available on time are essential for successful manufacturing. We must manage our inventory and make sure the materials meet our standards.

Measurement

- Measurement means using tools to track and monitor our manufacturing process. We use metrics and indicators to measure production output, cycle times, and defects. It helps us understand how well we are doing and identify areas for improvement.

Mother Nature (Environment)

- This category considers the impact of the environment on the process, such as temperature, humidity, lighting, and other external factors that can affect operations.

Management

- Management is about leading and making decisions in our manufacturing organization. Good management practices like strategic planning, resource allocation, and continuous improvement are critical for efficiency, productivity, and quality.

Maintenance

- Maintenance covers the upkeep, repair, and preventive maintenance activities performed on equipment and machinery. It includes scheduled maintenance, breakdown maintenance, and the overall reliability of the maintenance processes.

The 8M’s in Manufacturing can evaluate and address factors that affect our manufacturing processes. By focusing on elements like – manpower, machinery, materials, methods, measurement, environment, mother nature, and management, we can optimize our operations, improve quality, and be more efficient. Continuously improving and managing these factors can help us stay competitive in the dynamic manufacturing industry.

Who should use The 8Ms in Manufacturing Framework template?

- Anyone operating in production and quality management teams can use the 8M framework to identify and analyze potential causes of problems or defects. The 8Ms represent eight categories of potential problem sources in a manufacturing process.

Why use this template?

- The fishbone template, or the Ishikawa diagram, is commonly used alongside the 8M framework. The fishbone template helps visually represent the cause-and-effect relationships among various factors that contribute to a problem.

- It helps identify potential causes in a structured manner. Overall, the fishbone template is an effective tool for visualizing the 8M framework and can be used to analyze and address manufacturing issues.

Curated from community experience and public sources: