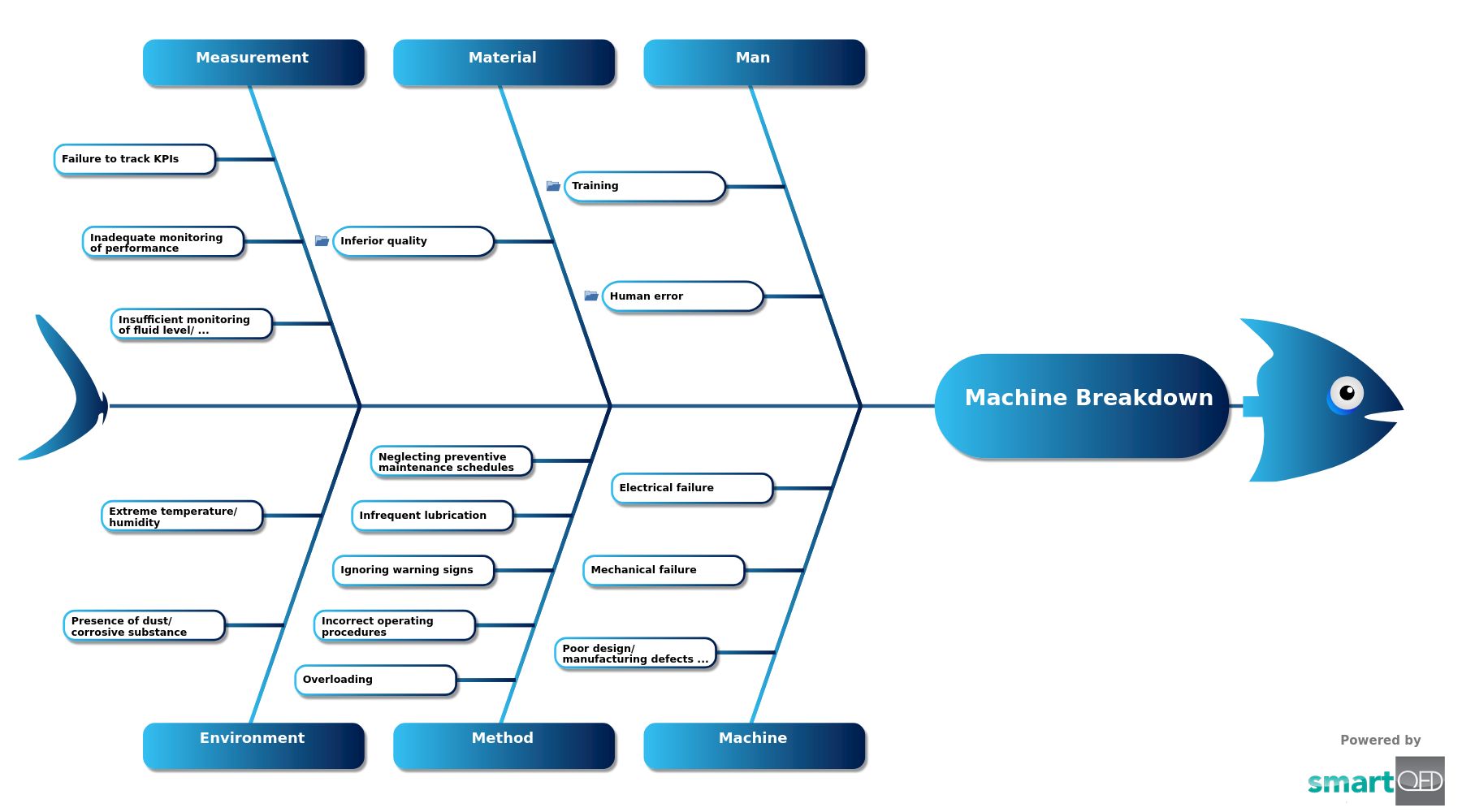

Reasons why a machine fails and ceases to work

Machine breakdowns are frequent in industrial and manufacturing environments, significantly impacting productivity, profitability, and business operations. Machine failure refers to the unexpected stoppage of a machine or equipment, leading to production downtime and delays in delivering products or services. It impacts productivity and efficiency in manufacturing industries. Irregular or insufficient maintenance leads to wear and tear of machine components, causing lubrication issues and the accumulation of dirt or debris. Furthermore, mechanical or electrical malfunctions in motors, bearings, or sensors can trigger sudden breakdowns. Improper usage, overloading, or negligence by operators contribute to stress, wear, or damage to machine parts, leading to failures. Environmental factors also play a significant role in accelerating machine degradation and breakdowns. Proper preventive measures are crucial for minimizing downtime and ensuring the smooth operation of machinery.

Machine Breakdown

Man

Machine

Material

Method

Measurement

Environment

Fishbone analysis, also known as Ishikawa or cause-and-effect analysis, is a method used to identify and understand the root causes of a problem or issue. In the context of machine breakdowns in industrial and manufacturing environments, Fishbone analysis helps to uncover various factors contributing to failures. Factors such as irregular maintenance, mechanical or electrical malfunctions, improper usage, environmental influences, and insufficient preventive measures can be systematically analyzed using the Fishbone diagram. By organizing and examining these causes, organizations can develop effective strategies to minimize downtime, enhance productivity, and ensure the smooth operation of machinery.

Curated from community experience and public sources: